ABOUT RECYCLING TECHNOLOGIES (SHORT VERSION)

Recycling Technologies converts Residual Plastic Waste into chemical feedstocks. The company was spun out from the University of Warwick in 2011. In early 2013, the it opened R&D and production facilities in Swindon to develop and manufacture the WarwickFBR™, its patented modular recycling units. Recycling Technologies’ machines can process up to 7,000 tonnes of waste per year, converting it from a problem into Plaxx™, a valuable low sulphur hydrocarbon.

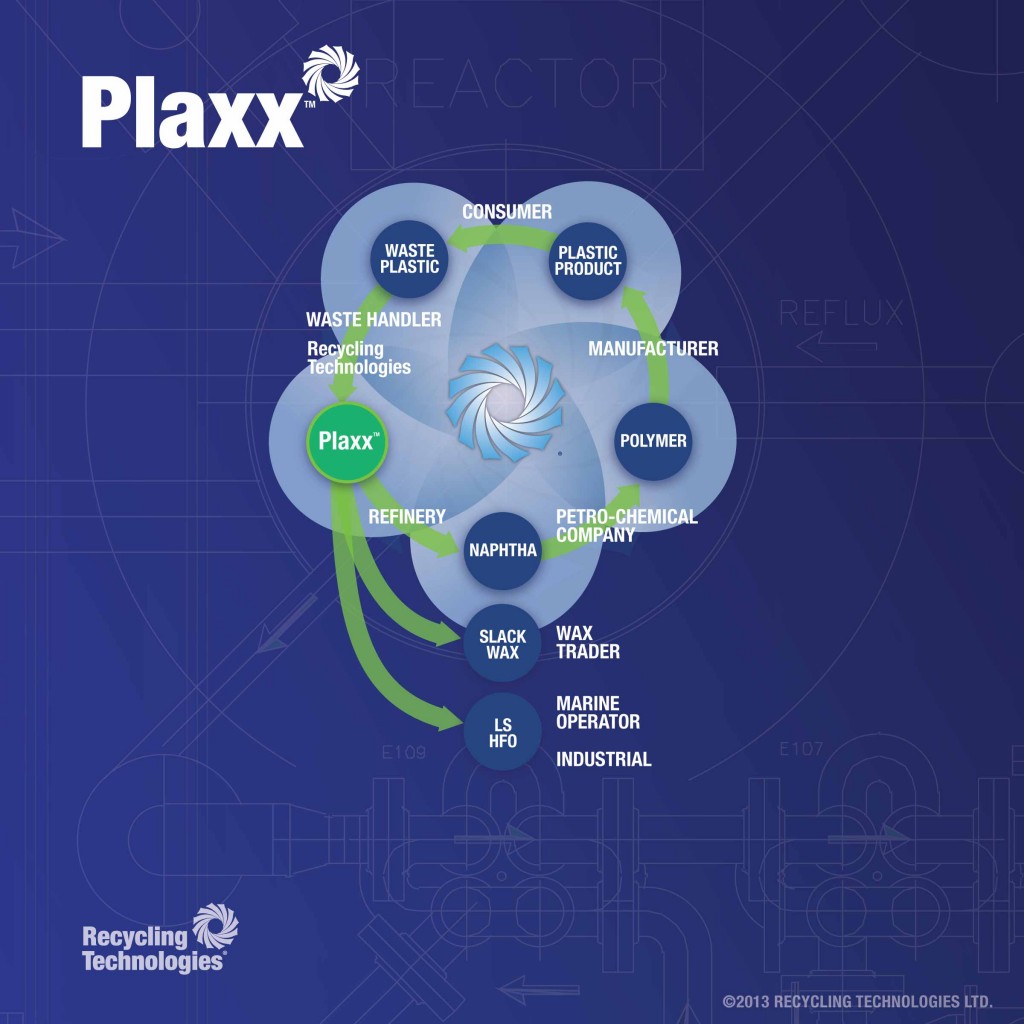

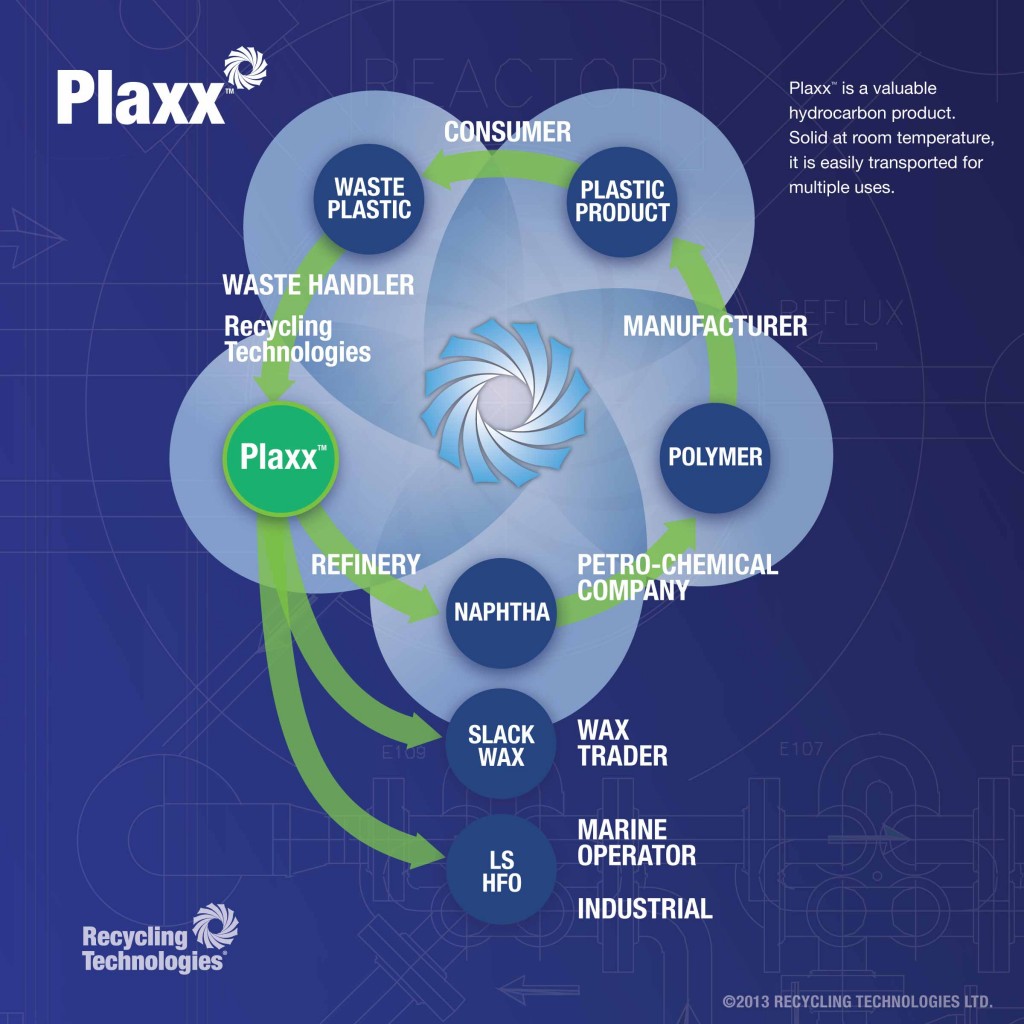

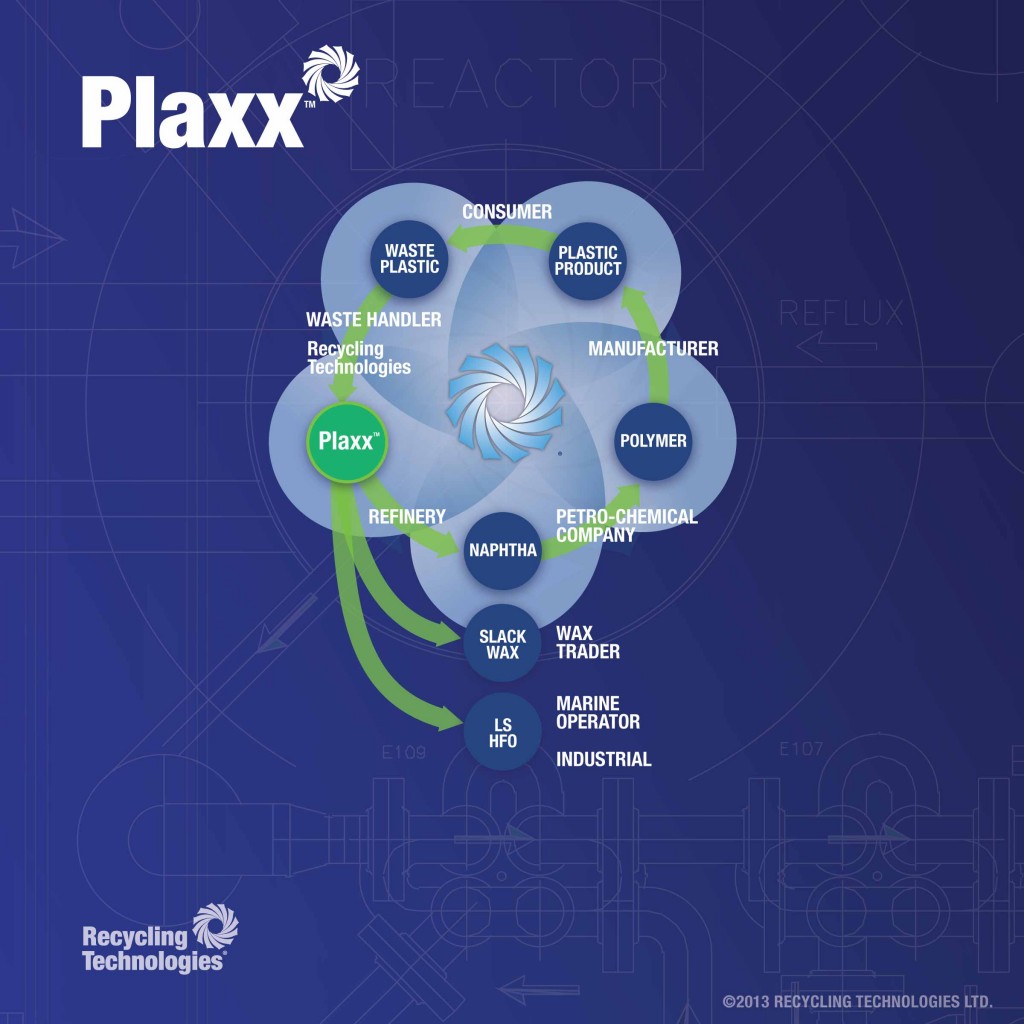

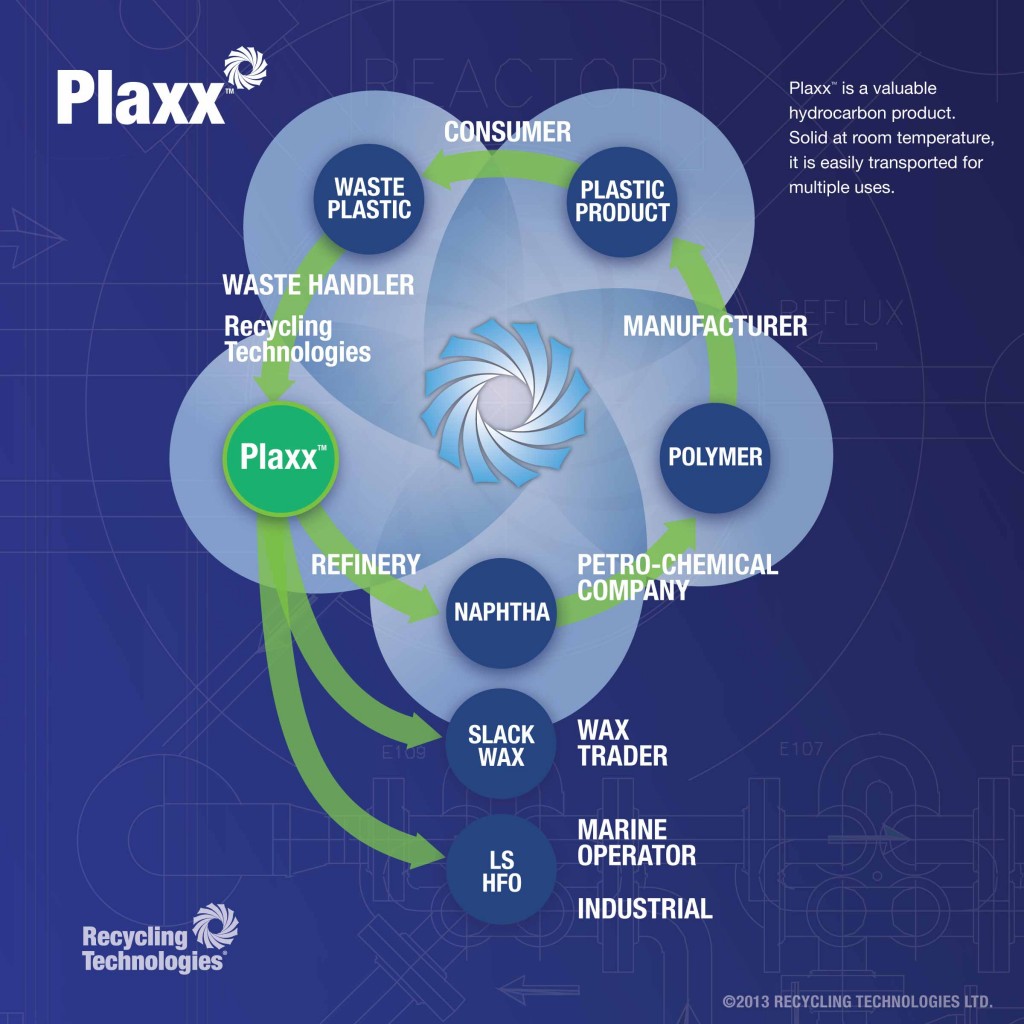

(Click on the images to see full-size graphic)

Recycling Technologies’ pilot plant, the RT700. (4000px)

Recycling Technologies’ pilot plant, the RT700. (4000px)

Recycling Technologies' pilot plant, the RT700. (4000px)

Recycling Technologies Swindon team photo (3000px)

Recycling Technologies Swindon team photo (3000px)

Recycling Technologies �has developed an innovative modular solution which converts Mixed Plastic Waste �into Plaxx™.

Plaxx™ cycle and applications (2400px)

Sample of Plaxx™ produced by the RT700 pilot plant (3700px)

Sample of typical residual waste plastic to be processed into Plaxx™

Sample of typical residual waste plastic to be processed into Plaxx™