APRIL 8th 2013, SWINDON. FOR IMMEDIATE RELEASE.

Recycling Technologies, a manufacturer of energy-from-waste equipment capable of generating electricity from mixed plastic waste, has opened their first design, testing and manufacturing plant at the South Marston Industrial Estate in Swindon.

The company was spun out of the University of Warwick in 2011, with assistance from Warwick Ventures Ltd, the university’s research commercialisation company. Now they have just opened their first design, testing and manufacturing plant in Swindon.

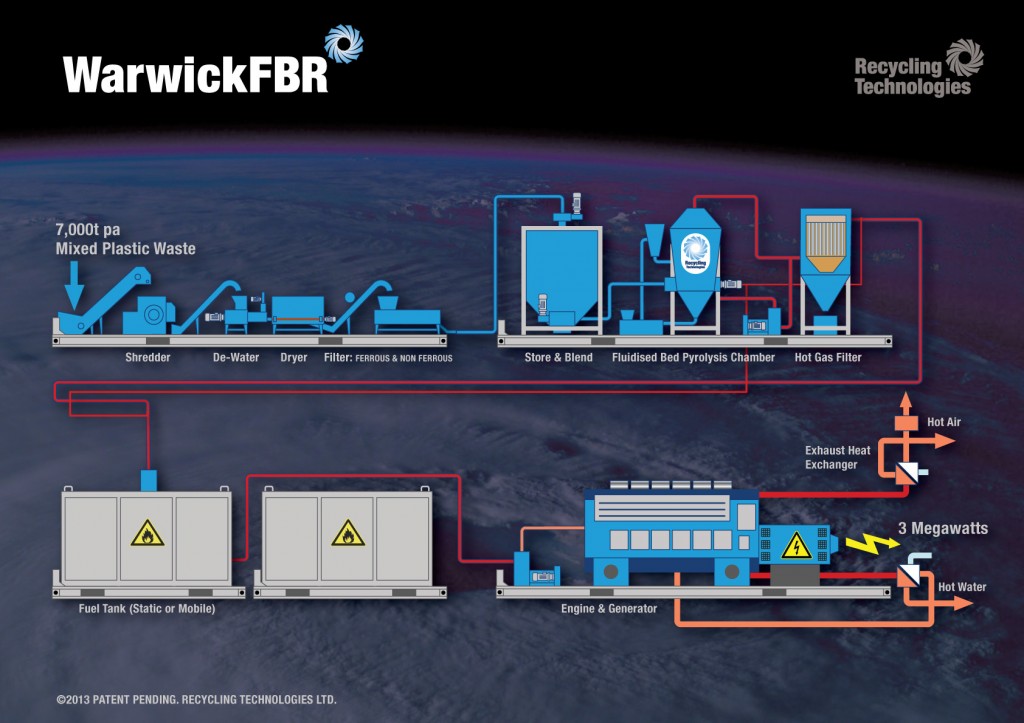

There they will manufacture their WarwickFBR, which is designed to produce heat and electricity from plastic – normally destined for landfill – using a process called Pyrolysis.

Unveiling a plaque marking the arrival of Recycling Technologies in Swindon, North Swindon MP Justin Tomlinson said: “It’s an honour to be invited to officially open Recycling Technologies’ new Technology and Manufacturing Centre.

Unveiling a plaque marking the arrival of Recycling Technologies in Swindon, North Swindon MP Justin Tomlinson said: “It’s an honour to be invited to officially open Recycling Technologies’ new Technology and Manufacturing Centre.

“When it comes to recycling, I’m a bit of a zealot, and so it’s great to see that Swindon has been chosen as the location for a new, exciting business, with a cutting edge technology that is generating jobs and helping solve environmental issues. Many of us are now concerned, as we discovered in the press this week that much of our plastic is ending up in landfill and not being used for the purpose that we thought. The waste to energy market is clearly going to be an important part of the UK’s energy supply mix and there is a real opportunity for Swindon to be at the heart of this.”

Today, according to the waste giant Viridor, 85% of plastic in the UK is still landfilled. Recycling Technologies say that its technology can eliminate this loss of a valuable fuel source by turning it instead into electricity and heat.

At the opening of the Recycling Technologies unit on Monday 8 April MD, Adrian Griffiths said: “There are many environmental benefits to this process, including enabling a reduction in the transportation of bailed plastics, a reduction in landfill, and the use of waste to create electricity rather than using virgin fossil fuels. Our system will produce enough fuel to generate up to 3 Megawatts of electricity and a similar amount of heat.

Using a process called “Pyrolysis”, the mixed plastics are transformed into gas, filtered to remove impurities and condensed to output a wax like fuel. This fuel can then be used in a suitable engine and generator in place of – for example – diesel.

Using a process called “Pyrolysis”, the mixed plastics are transformed into gas, filtered to remove impurities and condensed to output a wax like fuel. This fuel can then be used in a suitable engine and generator in place of – for example – diesel.

The firm currently has five staff and aims to grow to 12 by the end of the year, and employ between 30 to 40 within two years.

Recycling Technologies has a strong team and a wide range of advisors including Peter Jones OBE, previously of waste management specialists Biffa, as well as the backing and research credentials of the Universities of Warwick and Birmingham.

Peter Jones OBE said: “Discarded plastic is no longer just waste destined for landfill. The technology already exists to turn our waste into a substitute for fossil fuels, and now it also becoming more affordable. We are witnessing a sea change in the economic case of this conversion and Recycling Technologies is at the forefront of it. And as an emerging industry it is a great career choice for anyone who’s looking optimistically to the future.”

Peter Jones OBE said: “Discarded plastic is no longer just waste destined for landfill. The technology already exists to turn our waste into a substitute for fossil fuels, and now it also becoming more affordable. We are witnessing a sea change in the economic case of this conversion and Recycling Technologies is at the forefront of it. And as an emerging industry it is a great career choice for anyone who’s looking optimistically to the future.”

Recycling Technologies is set to drive forward an innovative solution to both the issues of managing what we do with our waste, as well as providing an alternative to fossil fuels in the short term.

To find out more about the arrival of Recycling Technologies, visit their website at recyclingtechnologies.co.uk.

Recycling Technologies initially approached Forward Swindon, the economic development and regeneration company, to assist with their move to Swindon. See more at www.swindon.uk.com